Modern logistics demand smarter strategies. Rising fuel costs, customer expectations, and tight margins push businesses to rethink delivery operations through data-driven optimization models that transform cost structures.

🚚 The Real Cost Behind Every Delivery Mile

Delivery expenses extend far beyond fuel consumption. Every package that leaves a warehouse carries hidden costs that erode profit margins: vehicle maintenance, driver wages, insurance premiums, failed delivery attempts, and reverse logistics. Transportation typically accounts for 50-60% of total logistics costs, making it the single largest expense category for businesses with physical product distribution.

Understanding the complete cost picture requires breaking down expenses into fixed and variable components. Fixed costs include vehicle leasing or depreciation, insurance, and base salaries. Variable costs fluctuate with delivery volume—fuel, overtime pay, packaging materials, and route-specific tolls. Companies that fail to track both categories accurately miss optimization opportunities worth thousands of dollars monthly.

The complexity multiplies when considering opportunity costs. A delivery vehicle stuck in traffic isn’t just burning fuel inefficiently—it’s missing potential deliveries, disappointing customers, and reducing daily throughput. These indirect costs rarely appear in traditional accounting but significantly impact overall operational efficiency.

📊 Traditional vs. Innovative Optimization Approaches

Conventional delivery planning relied on driver experience and basic geographic clustering. Dispatchers assigned routes based on postal codes and manual workload balancing. While this approach worked for decades, it leaves substantial savings untapped in today’s complex delivery networks.

Modern optimization models leverage algorithmic intelligence to process variables humans cannot manage simultaneously. These systems analyze delivery windows, traffic patterns, vehicle capacity, driver skills, customer preferences, and historical data to generate mathematically optimized routes. The difference in efficiency between traditional and algorithmic approaches often exceeds 20-30% in fuel consumption and delivery time.

Dynamic Route Optimization Technology

Static route planning assumes conditions remain constant throughout the day—a dangerous assumption in real-world logistics. Dynamic optimization continuously recalculates routes based on changing conditions: unexpected traffic congestion, new urgent orders, delivery cancellations, or vehicle breakdowns.

Machine learning algorithms predict congestion patterns by analyzing historical traffic data alongside real-time inputs. These systems learn that certain intersections bottleneck between 3-4 PM on weekdays or that weather conditions impact specific route segments disproportionately. By incorporating these patterns, dynamic systems reroute proactively rather than reactively.

💡 Core Optimization Models Driving Cost Reduction

Several mathematical frameworks power modern delivery optimization, each addressing specific logistics challenges. Understanding these models helps businesses select appropriate solutions for their operational contexts.

Vehicle Routing Problem (VRP) Solutions

The Vehicle Routing Problem represents the foundation of delivery optimization. VRP algorithms determine optimal delivery sequences for multiple vehicles serving numerous locations while respecting constraints like capacity limits, time windows, and maximum route duration. Standard VRP variations include:

- Capacitated VRP: Accounts for vehicle load limits and delivery volumes

- VRP with Time Windows: Honors specific delivery timeframes requested by customers

- Multi-Depot VRP: Optimizes routes across multiple distribution centers

- VRP with Pickup and Delivery: Manages simultaneous forward and reverse logistics

Advanced VRP implementations reduce total distance traveled by 15-25% compared to manual routing. This translates directly to fuel savings, extended vehicle lifespan, and increased daily delivery capacity without adding resources.

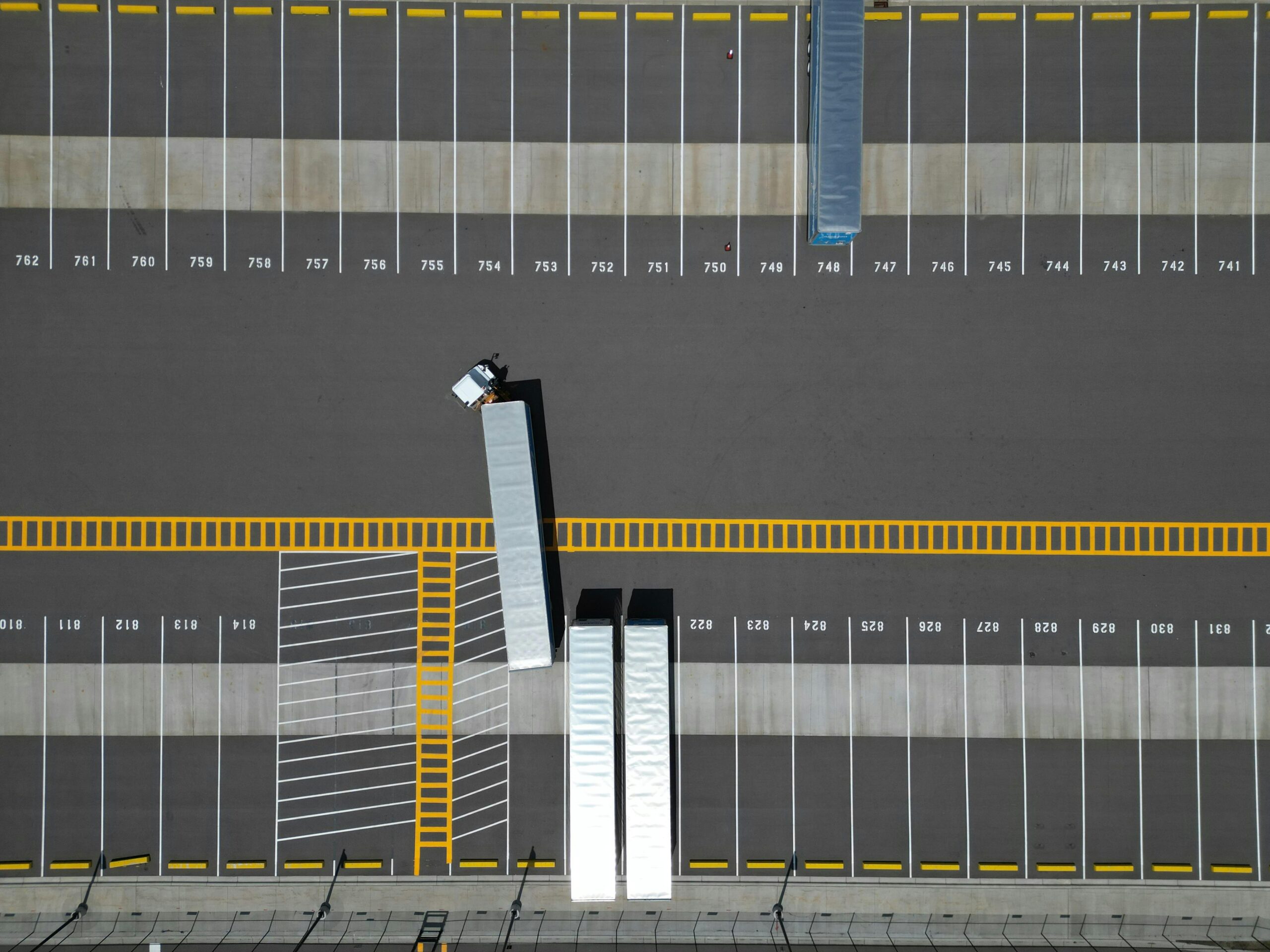

Clustering and Zoning Strategies

Geographic clustering groups deliveries into logical zones before applying detailed route optimization. This two-phase approach manages computational complexity in large-scale operations while maintaining solution quality. Clustering algorithms consider delivery density, access patterns, and service requirements to create balanced zones.

Effective zoning prevents drivers from crisscrossing territories unnecessarily. A well-designed zone system ensures each driver operates within a defined geographic area, reducing total mileage and enabling drivers to develop area expertise. Familiarity with specific neighborhoods improves delivery speed and accuracy.

🔄 Real-Time Adaptation and Predictive Analytics

The most powerful optimization systems don’t just plan routes—they predict problems and adapt continuously. Predictive analytics identify patterns that human dispatchers miss, enabling proactive decision-making that prevents costly disruptions.

Weather impact modeling exemplifies predictive optimization value. Systems analyze forecast data to anticipate how conditions affect delivery times in specific areas. Rain might slow urban deliveries by 15% but delay rural routes by 35%. Advanced systems adjust schedules and communicate realistic delivery windows to customers automatically, reducing failed deliveries and customer complaints.

Machine Learning for Demand Forecasting

Accurate demand prediction enables better resource allocation and cost management. Machine learning models analyze historical order patterns, seasonal trends, promotional calendars, and external factors like local events or holidays to forecast delivery volumes with increasing accuracy.

Businesses using predictive demand models optimize fleet sizing, staffing levels, and inventory positioning. Rather than maintaining excess capacity for unexpected volume spikes, they scale resources precisely to anticipated demand. This eliminates unnecessary fixed costs while maintaining service quality during peak periods.

📱 Technology Integration for Seamless Operations

Optimization models deliver maximum value when integrated into comprehensive logistics management systems. Modern platforms connect route planning, driver communication, customer notifications, and performance analytics into unified ecosystems.

Mobile applications empower drivers with turn-by-turn navigation, digital proof of delivery, customer contact information, and real-time dispatch communication. This eliminates paperwork, reduces administrative time, and provides visibility into delivery status for all stakeholders. GPS tracking ensures route compliance while gathering data for continuous optimization improvement.

Customer-facing applications transform delivery from a necessary transaction into a value-added experience. Real-time tracking, precise delivery windows, and proactive communication reduce anxiety and support requests. These features increase customer satisfaction while decreasing operational costs associated with “where is my order” inquiries.

💰 Quantifying Savings Through Optimization Metrics

Measuring optimization impact requires tracking specific key performance indicators that connect directly to cost efficiency. Businesses should monitor these metrics before and after implementing new optimization strategies:

| Metric | Definition | Target Improvement |

|---|---|---|

| Cost per Delivery | Total delivery expenses divided by deliveries completed | 15-25% reduction |

| Miles per Delivery | Total distance traveled divided by successful deliveries | 20-30% reduction |

| On-Time Delivery Rate | Percentage of deliveries completed within promised window | 95%+ achievement |

| Failed Delivery Rate | Percentage of delivery attempts requiring rescheduling | Below 5% |

| Driver Utilization | Percentage of shift time spent on productive delivery activity | 75-85% utilization |

Regular metric review identifies optimization opportunities and validates strategy effectiveness. Businesses achieving significant improvements typically see ROI on optimization investments within 3-6 months through direct cost reductions and capacity increases.

🌍 Environmental Impact and Sustainability Benefits

Cost optimization naturally aligns with environmental responsibility. Reduced mileage directly translates to lower carbon emissions, positioning optimized logistics as both economically and ecologically beneficial. Many businesses discover that sustainability goals and cost reduction objectives support rather than conflict with each other.

Route optimization reduces fuel consumption, which constitutes the largest environmental impact in delivery operations. A 20% reduction in miles traveled means 20% fewer greenhouse gas emissions without requiring fleet electrification or alternative fuel investments. These immediate gains complement longer-term sustainability initiatives.

Customers increasingly value environmental responsibility. Businesses that communicate optimization-driven sustainability improvements strengthen brand perception while reducing costs. Transparent reporting on emissions reduction demonstrates corporate responsibility that resonates with environmentally conscious consumers.

🔧 Implementation Strategies for Maximum Impact

Successful optimization implementation requires more than technology deployment. Organizations must address process changes, staff training, and change management to realize full efficiency potential.

Phased Rollout Approach

Beginning with pilot programs in limited geographic areas or specific delivery types reduces implementation risk. Pilots generate quick wins that build organizational momentum while identifying challenges before full-scale deployment. Start with the most problematic routes or highest-cost delivery segments to maximize early ROI visibility.

Collect baseline metrics before implementation to demonstrate improvement quantitatively. Document current performance in detail—total costs, delivery times, customer satisfaction scores, and driver feedback. This baseline becomes essential for measuring optimization success and justifying expanded investment.

Driver Engagement and Training

Drivers represent the front line of delivery operations. Their buy-in determines whether optimization systems succeed or fail. Involve drivers early in the selection process, soliciting feedback on system usability and route recommendations. Frame optimization as a tool that makes their jobs easier rather than surveillance that questions their judgment.

Comprehensive training ensures drivers understand new systems and trust algorithmic recommendations. Explain how optimization works, what data it considers, and why suggested routes improve efficiency. Drivers who understand the logic behind recommendations follow them more consistently, maximizing system effectiveness.

🚀 Advanced Optimization Techniques for Competitive Advantage

Leading logistics operations push beyond basic route optimization to leverage cutting-edge techniques that create sustainable competitive advantages.

Autonomous Delivery Vehicle Integration

Autonomous vehicles and drones represent the delivery future, but current optimization models already prepare for this transition. Hybrid optimization systems that coordinate human drivers with autonomous assets maximize flexibility while reducing labor costs in appropriate scenarios.

Urban drone delivery for small packages under specific weight thresholds offers cost advantages in high-density areas. Optimization algorithms determine which deliveries suit autonomous methods and which require human drivers based on package characteristics, destination accessibility, and regulatory constraints.

Collaborative Logistics Networks

Shared delivery networks pool resources across multiple businesses, spreading fixed costs and improving vehicle utilization. Optimization models coordinate multi-company deliveries, determining optimal collaboration scenarios that benefit all participants without compromising service quality or competitive information.

Collaborative networks particularly benefit businesses with complementary delivery patterns—morning deliveries paired with afternoon returns, or weekday operations matched with weekend specialists. Shared infrastructure reduces per-delivery costs while maintaining the service standards customers expect.

⚡ Overcoming Common Implementation Challenges

Organizations encounter predictable obstacles when implementing optimization systems. Anticipating these challenges enables proactive solutions that accelerate value realization.

Data quality issues undermine optimization effectiveness. Algorithms require accurate address information, realistic service times, and precise vehicle specifications. Invest in data cleaning and validation before full implementation. Establish ongoing data governance processes to maintain quality as operations scale.

Resistance to change appears in every optimization initiative. Experienced dispatchers may resent algorithmic suggestions that contradict their intuition. Address this through transparent communication about how systems work and evidence-based performance comparisons. Most resistance dissipates when skeptics observe consistent efficiency improvements.

Integration complexity with existing systems creates technical hurdles. Modern optimization platforms offer APIs and standard integrations for popular logistics management systems, but custom configurations often require specialized expertise. Budget adequate implementation support and consider phased integration that prioritizes high-value connections.

📈 Future Trends Reshaping Delivery Optimization

Optimization technology continues evolving rapidly. Understanding emerging trends helps businesses prepare for next-generation capabilities that will define competitive logistics operations.

Artificial intelligence advances enable increasingly sophisticated optimization that handles greater complexity with less human oversight. Neural networks learn optimal strategies through experience, continuously improving recommendations without explicit programming. These systems identify subtle patterns that traditional algorithms miss.

Internet of Things sensors provide granular real-time data about vehicle condition, cargo status, and environmental factors. Optimization systems incorporating IoT inputs make more informed decisions—rerouting refrigerated deliveries when temperature deviations occur or scheduling preventive maintenance before breakdowns disrupt operations.

Blockchain technology promises transparent, tamper-proof delivery verification that reduces disputes and streamlines payment processing. Smart contracts automatically trigger payments upon delivery confirmation, improving cash flow for carriers while reducing administrative overhead.

🎯 Building Your Optimization Roadmap

Successful optimization requires strategic planning aligned with specific business objectives. Organizations should develop comprehensive roadmaps that sequence initiatives for maximum cumulative impact.

Begin by assessing current state capabilities and identifying specific pain points. Which cost categories consume the largest budget shares? Where do customer complaints concentrate? What operational inefficiencies frustrate staff most? Answers to these questions prioritize optimization investments toward areas with greatest improvement potential.

Define clear success criteria before implementation. Vague goals like “improve efficiency” lack accountability. Specific targets—reduce cost per delivery by 18%, increase on-time performance to 96%, decrease failed delivery rate below 4%—create measurable objectives that guide technology selection and validate results.

Partner with optimization vendors that demonstrate industry expertise and proven results. Request case studies from similar businesses, references from current customers, and trial periods that allow hands-on evaluation. The right partner provides not just technology but strategic guidance that accelerates value realization.

Mastering delivery cost efficiency through innovative optimization models transforms logistics from a necessary expense into a strategic advantage. Organizations that embrace data-driven routing, predictive analytics, and continuous improvement position themselves for sustainable growth in increasingly competitive markets. The question isn’t whether to optimize delivery operations—it’s how quickly you can implement strategies that competitors will eventually be forced to adopt. Start your optimization journey today, and the savings will compound for years to come.

Toni Santos is a logistics analyst and treaty systems researcher specializing in the study of courier network infrastructures, decision-making protocols under time constraints, and the structural vulnerabilities inherent in information-asymmetric environments. Through an interdisciplinary and systems-focused lens, Toni investigates how organizations encode operational knowledge, enforce commitments, and navigate uncertainty across distributed networks, regulatory frameworks, and contested agreements. His work is grounded in a fascination with networks not only as infrastructures, but as carriers of hidden risk. From courier routing inefficiencies to delayed decisions and information asymmetry traps, Toni uncovers the operational and strategic tools through which organizations preserved their capacity to act despite fragmented data and enforcement gaps. With a background in supply chain dynamics and treaty compliance history, Toni blends operational analysis with regulatory research to reveal how networks were used to shape accountability, transmit authority, and encode enforcement protocols. As the creative mind behind Nuvtrox, Toni curates illustrated frameworks, speculative risk models, and strategic interpretations that revive the deep operational ties between logistics, compliance, and treaty mechanisms. His work is a tribute to: The lost coordination wisdom of Courier Network Logistics Systems The cascading failures of Decision Delay Consequences and Paralysis The strategic exposure of Information Asymmetry Risks The fragile compliance structures of Treaty Enforcement Challenges Whether you're a supply chain strategist, compliance researcher, or curious navigator of enforcement frameworks, Toni invites you to explore the hidden structures of network reliability — one route, one decision, one treaty at a time.